Cold Elongation Testing Machine as per BS EN 60811-505 & IEC 60811-505

Cold Elongation test as per BS EN 60811-505 or IEC 60811-505from Tech trivial is a machine all fit inside with automatic elongation apparatus fit inside the cold chamber. The operator easily prepare sample and fix it before test is started and without opening the door thanks to HMI display and controller. High Quality loadcell and software is also provided with the equipment to make reporting easier and accurate with high precision.

Software Features:

- Full Machine Control, Start/Stop Elongation, Home Position

- Pre-programmable Sample Test Types removing the hassle of entering Sample Details and Type every time

- Display of Load Applied, Displacement and Temperature

- Speed Control to vary speed as per test requirement

- Simultaneous LIVE graph visibility (Load v/s Displacement) (Stress v/s Strain)

- Selectable Report formats to suit every client and test specific needs

- Tabular Data for Test with Graph recording for in-view software

Cold Elongation Test Machine as per BS EN 60811-505 or IEC 60811-505. Cold Elongation Testing Machine is conducted to fulfill the necessities of BS EN 60811-505. it’s performed on the insulation and sheathing materials of electrical cables and fibre optic cables with a diameter in way over 12.5mm. Cables of a smaller diameter are more commonly subject to the Cold Bend Test to IEC 60811-504.

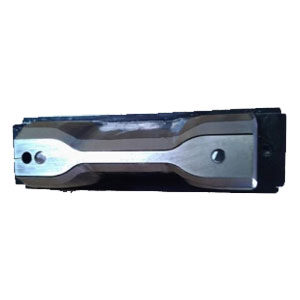

From the prepared sample of cable insulation (thickness between 0.6mm and 2mm) and which has been conditioned at ambient temperature, 2 dumb-bell shaped test samples are punched vertically within the material; ideally these test samples should come from side-by-side.

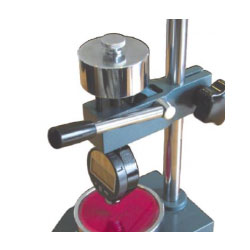

These test samples are then placed in an exceedingly pre-cooled cooling chamber. they’re fixed to the tensile and elongation apparatus with clamps at the highest and bottom, leaving 30mm of sample between them. they’re then left to condition for two hours. Once conditioned, the clamps then pull in opposite directions at a speed of 25mm/min, elongating the test samples until the purpose of break.

Tensile Cooling Chamber slides inwards to enclose the grips inside the cooling chamber. The cooling chamber is a refrigerant based cascade type system with dual/single compressor depending upon temperature requirements. The standard model is capable to perform tests up to a working temperature of – 400C

The elongation testing machine is decided by measuring the gap from start point to point of rupture. to attain a pass during this test, the elongation must have achieved a minimum 20% increase on the first test sample size before breaking.

Specialized Pneumatic Grips

- Twin Column Servo Drive Computer controlled cum Electromechanical Tensile Test Machine attached with Cooling Chamber for up to minus 150C

- 3kN/300kgf Capacity

- Twin Ball Screw (Hiwin, Taiwan) or equivalent

- Gear Box (Bonfiglioli, Italy) or equivalent

- Actuator: Servo Panasonic

Cold Elongation Test Machine as per BS EN 60811-505 & IEC 60811-505

You can also check our more Machinery Products.

You may also like…

-

General & Physical Tests

Low & Ultra-Low Temp Cold Chamber Machine (for -0 to -86 C )

- Cold Chamber Size (as per requirement of customer)

- Digital Temperature Indicating controller

- Glass Window on the door. (if required)

- Very high displacement compressor of about 22 per revolution

- Highly efficient refrigerant R404A having a boiling pt. Of -46DegC

- Our freezer does not require a low ambient temp. It can work even at an ambient of 40DegC

- Feed evaporator to improve the refrigeration effect and coeff. Of performance of the system as a whole

- High density PUF of about 60kg/cm3 so as to hold the temperature for a longer time

- Hot discharge is circulated on the mouth of the freezer to prevent cooling losses

- Microprocessor based temperature controller for accurate temperature and longer compressor life.

- Standard compressor of 1 hp with Cascading Refrigeration System

- Copper Capillary of higher wall thickness to last longer

- Uniform capillary distribution on the surface of chamber for faster and uniform cooling within chamber.

- Double door formation (acrylic + normal) for better insulation

- Noise less operations

SKU: n/a -

General & Physical Tests

Horizontal Cold Chamber up to -86 deg

Techtrivial designs and develop many ranges of cold chambers for cable and plastic compounding industry. Our range goes from -23 Degree Celsius to -86 degree Celsius where you can test not only servo cables with -15 degree Celsius operating temperature but also Arctic grade cables up to -86 degree Celsius.

SKU: n/a -

General & Physical Tests

Vertical Cold Chamber upto -86 deg

Cold chambers are and integral part of any cable test laboratory. They are helpful in performing cold bending, cold elongation and cold impart tests as per latest revision of IEC-60811 5 and 6 series. Techtrivial has many different designs and sizes for vertical cold chambers ranging from -15 degree Celsius to -86 degree Celsius.

SKU: n/a