Universal Tensile Strength Testing Machine for Plastics

<p class="stock in-stock"></p>

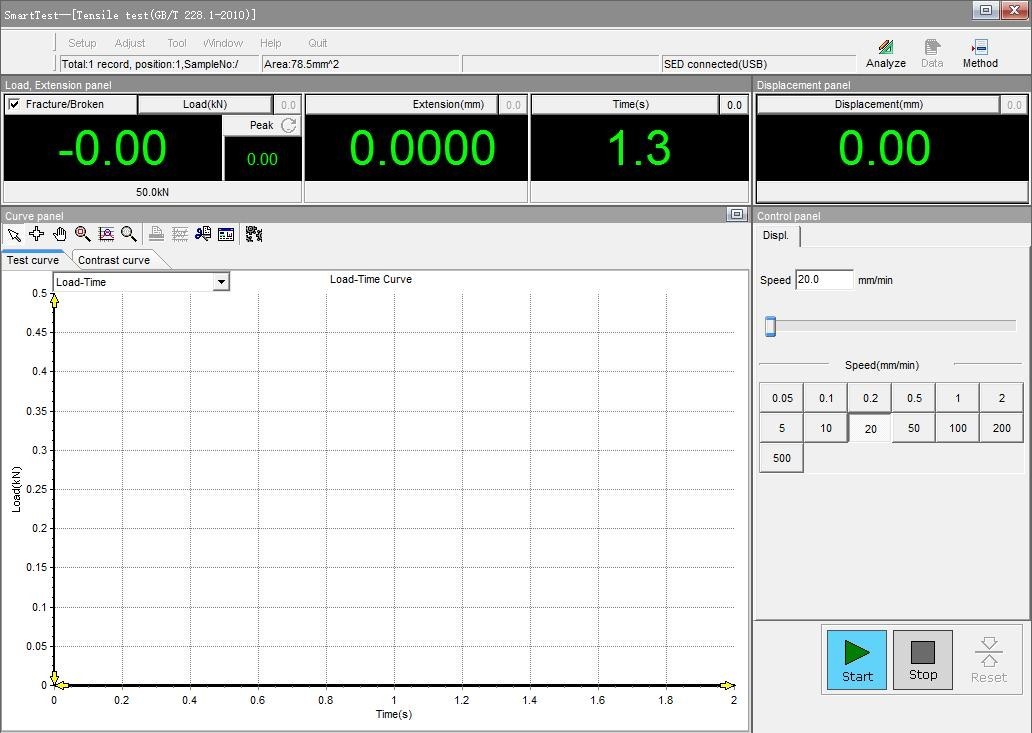

Universal tensile test machine are largely used as cable and plastic test equipment. The tester can complete one test with a simple five-step operation: select the existing test method, input the sample size, install the sample, start the test, and print the report. There two models with different variants of force as per the requirements of customers.

- Single column UTM invariants from 0.5KN to 10KN.

- Dual column UTM invariants from 1KN to 15KN.

Universal Tensile Strength Testing Machine Application

Tensile Strength Testing Machine mainly called a universal tensile testing machine is used for testing a wide range of materials for tension, compression, bending, shearing, and low cycle test. Suitable for metal, rubber, plastic, spring, textile, and components testing, it is widely used in the corresponding industries, research, and development, test institutes, training centers, etc.

EN 60811-302 Electric and optical fiber cables – Test methods for non-metallic materials – Part 302: Electrical tests – Measurement of the d.c resistivity at 23 °C and 100 °C of filling compounds – IEC 60811-302:2012 gives the procedure to examine the d.c.

UTM: Universal testing machine

Standards

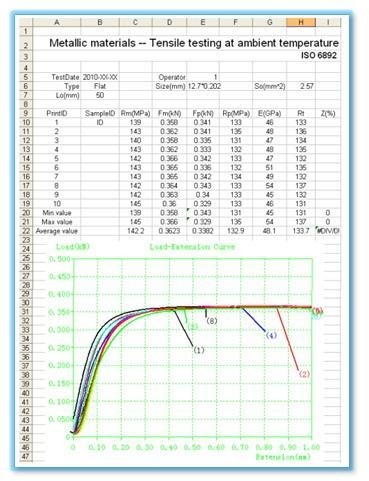

ASTMA370, ASTME4, ASTME8, ASTME9, ISO6892, ISO7438, ISO7500-1, EN10002-4, GB/T228-2002, GB 16491-2008, HGT 3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849-2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430, EN 60811 etc.

Standard EN 60811

Safety Device

Stroke protection

Force protection

Emergency stop

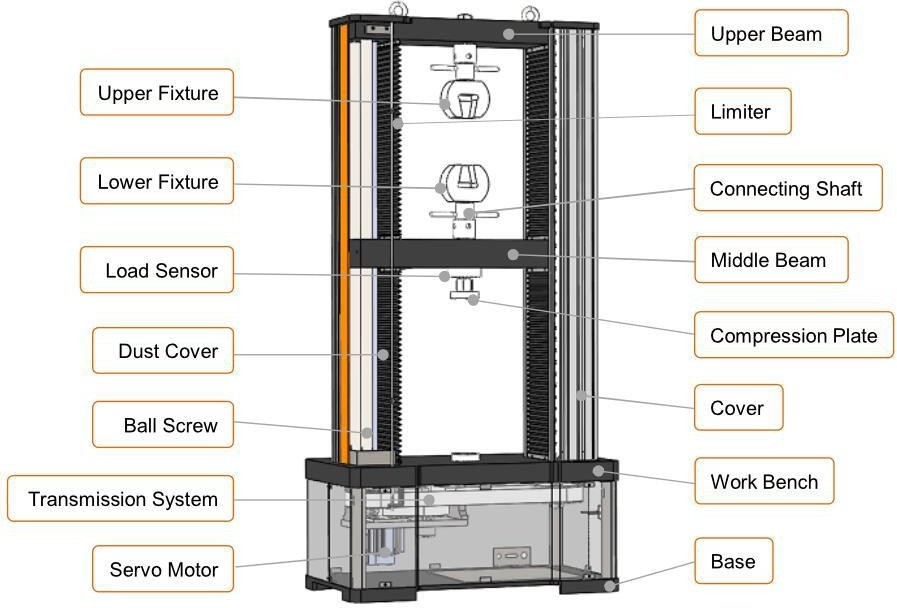

Construction

Machine rack

Rugged Dual column structure, cross-head movement upward for tensile tests Ball screw drive to ensure precision control of test force and tensile speed.

The encoder is the displacement sensor, with high resolution, and strong anti-interference ability.

The shield plate with a limit mechanism (Limit Switches) is used to control the beam moving range to avoid sensor damage due to the large mechanical moving distance acting as a safety protection

Transmission system

Planetary reducer, belts, and ball screws consist of the transmission system to make transmission more accurate and stable. High grade no gap ball screws (Raceway grinding by German technology to make the beam moving more stable and effectively reduces the equipment gap

Model |

M25 M50 |

M10 |

| Max. Load(kN) | 25 OR 50 | 10 |

| Load accuracy | Class 1 | Class 0.5 |

| Load range | 2%~100%F·S | 0.2%~100%F·S |

| Load resolution | 1/300000 | |

| Resolution of deformation | 0.04um | |

| Accuracy of displacement | Within±0.5%of indicating load | |

| Resolution of displacement | 0.01mm | |

| Test speed(mm/min) | 0.05-1000 step less arbitrary setting | |

| Speed accuracy | within ±1% / ±0.5% of set speed | |

| E-Tensile space(mm) | 800 (can be customized) | |

| E-Compression space(mm) | 800 (can be customized) | |

| D-Test width(mm) | 400 (can be customized) | |

| F-Beam travel distance(mm) | 1140 | |

| H-Workbench thickness(mm) | 30 | |

| I-Base height(mm) | 210 | |

| Power supply | AC220V±10%,50Hz/60Hz (can be customized) | |

A universal testing machine consists of two main parts :

- Loading Unit

- Control Unit

The main components of the control unit in a universal testing machine are :

- Hydraulic Power Unit

- Load Measuring Unit

- Control Devices

Frequently asked questions:-

what is the universal testing machine?

A universal testing machine (UTM), also known as a universal tester, materials testing machine, or materials test frame, is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. The “universal” part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures

How does a universal testing machine work?

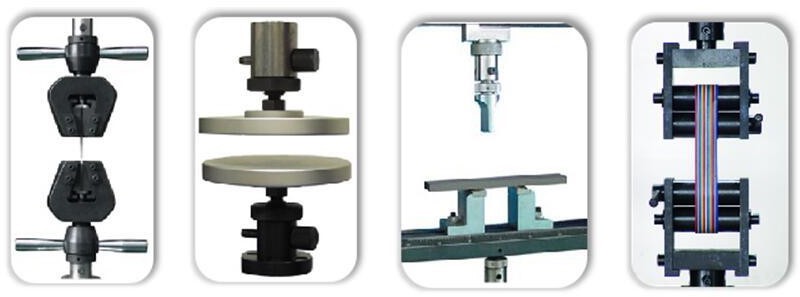

Materials testing machine that is categorized as universal can be used to perform tests in tensile and compression directions on a wide range of materials for many different applications. The universal tester tends to be modular in design, which allows the user to switch from the compression direction (pressing) to the tensile direction (pulling), and test at loads ranging from 0.5 kN up to 5,000 kN and at a high test-speed range that can be used without restriction. In addition, universal test machines allow for easy adaptation of the necessary fixtures and accessories (specimen grips, compression platens, extensometers, load cells, etc.) for a particular material and application.

You can also check our more Machinery Products.

EN 60811 Universal Tensile Strength Testing Machine for Plastics

Model |

M25 M50 |

M10 |

| Max. Load(kN) | 25 OR 50 | 10 |

| Load accuracy | Class 1 | Class 0.5 |

| Load range | 2%~100%F·S | 0.2%~100%F·S |

| Load resolution | 1/300000 | |

| Resolution of deformation | 0.04um | |

| Accuracy of displacement | Within±0.5%of indicating load | |

| Resolution of displacement | 0.01mm | |

| Test speed(mm/min) | 0.05-1000 step less arbitrary setting | |

| Speed accuracy | within ±1% / ±0.5% of set speed | |

| E-Tensile space(mm) | 800 (can be customized) | |

| E-Compression space(mm) | 800 (can be customized) | |

| D-Test width(mm) | 400 (can be customized) | |

| F-Beam travel distance(mm) | 1140 | |

| H-Workbench thickness(mm) | 30 | |

| I-Base height(mm) | 210 | |

| Power supply | AC220V±10%,50Hz/60Hz (can be customized) | |