Smoke Density Tester 61034

<p class="stock in-stock"></p>

Smoke density test as per IEC 61034-1 and 2 is one of the most required test in the market for PVC and LSZH insulated/extruded cables.

The ROI of the instrument can be achieved with 1 year considering 3 tests per month.

Smoke Density Tester IEC 61034

Buy smoke density chamber or smoke density tester IEC-61034 is all about the assessment of plastic used on a cable. This test is also integrated with the new CPR regulation in Europe for cables in EN 50399 and EN 50750.

In the case of fire, the smoke has many effects, one of the worst being visibility reduction.

It delays escaping from buildings, as the smoke is quickly felt like an impenetrable barrier

affecting breathing and irritating the eyes. Visibility (m) is assessed through smoke

opacity, by calculating its optical density, extinction coefficient or transmittance.

Finally, the effect of opacity on people is determined using models that take into

account the object they want to see through the smoke.

3.1 Transmittance

Transmittance is the ratio of transmitted light intensity through the smoke to incident light

intensity under specified conditions. It is dimensionless and is usually expressed as a

percentage. Without any smoke its value is 100%, decreasing with the smoke release.

I0: light intensity measured in the absence of smoke/transmittance = 100%

I: light intensity measured with smoke density tester IEC-61034

3.2 Optical density

The Beer-Lambert law defines light absorption of a material, depending on its

properties. It can be used to determine the attenuation of light through the smoke for

a given path length. The optical density is usually obtained by measuring the

attenuation of a light beam passing through the smoke, using the Lambert-Beer law.

One of the main testing methods in the cable industry to assess the smoke

production potential in the case of a fire is described in the IEC/EN61034-1 and -2

standards (smoke density tester IEC-61034 ). Cables are placed above a tank containing a specific fire source, mainly

ethanol, in a 27 m3cabin.

When the cable materials burn, smoke is released,

reducing the light intensity in the test chamber. This attenuation is measured by a

photocell placed in front of a white light beam at a fixed distance: path length of 3 m.

The final result is given in terms of transmittance, (%). Without any other

specification, the normal pass/fail criterion is 60% of light transmittance.

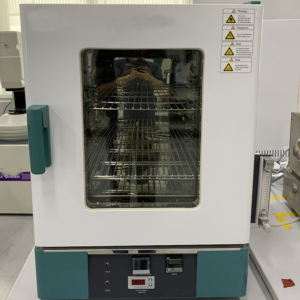

The Smoke Density Tester IEC 61034 consists of:-

- 3-meter cube double-walled 2 mm thick steel chamber

- Mixing Fan

- Exhaust system

- Flame panels

- Ethanol tray

- Sample holder

- The light source of 3500-3000K

- White light detecting diode equivalent to the human eye

- Computer with copyright software for control and reporting of the entire setup

Smoke Density Tester IEC 61034

Auf Deutsch:

Kaufen Sie Rauchdichtheitstest 61034 ist alles über die Beurteilung der Kunststoff auf ein Kabel verwendet. Diese Prüfung ist auch in die neue CPR-Verordnung in Europa für Kabel in EN 50399 und EN 50750 integriert.

Im Brandfall hat der Rauch viele Auswirkungen, eine der schlimmsten ist die Sichtbarkeitsreduzierung.

Er verzögert den Austritt aus Gebäuden, da der Rauch schnell wie eine undurchdringliche Barriere empfunden wird.

die die Atmung beeinträchtigen und die Augen reizen. Die Sichtbarkeit (m) wird durch Rauch bewertet.

Opazität durch Berechnung ihrer optischen Dichte, ihres Extinktionskoeffizienten oder ihres Transmissionsgrades.

Schließlich wird die Wirkung der Opazität auf den Menschen mit Hilfe von Modellen bestimmt, die

das Objekt, das sie durch den Rauch sehen wollen.

3.1 Durchlässigkeit

Der Transmissionsgrad ist das Verhältnis der durch den Rauch durchgelassenen Lichtintensität zum einfallenden Licht

Intensität unter bestimmten Bedingungen. Sie ist dimensionslos und wird in der Regel als

Prozentsatz. Ohne Rauch ist sein Wert 100%, der mit der Rauchfreisetzung abnimmt.

I0: Lichtintensität gemessen in Abwesenheit von Rauch/Durchlässigkeit = 100%.

I: Lichtintensität gemessen mit Rauch

3.2 Optische Dichte

Das Beer-Lambert-Gesetz definiert die Lichtabsorption eines Materials in Abhängigkeit von seiner

Eigenschaften. Es kann zur Bestimmung der Lichtdämpfung durch den Rauch für

eine vorgegebene Weglänge. Die optische Dichte wird in der Regel durch Messung der

Abschwächung eines Lichtstrahls, der den Rauch durchquert, unter Anwendung des Lambert-Beer-Gesetzes.

Eine der wichtigsten Prüfmethoden in der Kabelindustrie zur Beurteilung des Rauchverhaltens

Das Produktionspotenzial im Brandfall ist in der IEC/EN61034-1 und -2 beschrieben.

Standards. Die Kabel werden über einem Tank mit einer bestimmten Feuerquelle verlegt, hauptsächlich

Ethanol, in einer 27 m3-Kabine.

Wenn das Kabelmaterial brennt, wird Rauch freigesetzt,

Reduzierung der Lichtintensität in der Prüfkammer. Diese Abschwächung wird durch eine

Fotozelle, die in einem festen Abstand vor einem weißen Lichtstrahl platziert wird: Weglänge 3 m.

Das Endergebnis wird in Bezug auf den Transmissionsgrad (%) angegeben. Ohne andere

Spezifikation beträgt das normale Pass/Fail-Kriterium 60% der Lichtdurchlässigkeit.

Die Ausstattung besteht aus:-

3-Meter-Würfel doppelwandig 2 mm dicke Stahlkammer

Mischventilator

Auspuffanlage

Flammen-Paneele

Ethanol-Schale

Probenhalter

Die Lichtquelle von 3500-3000K

Weißlicht-Erfassungsdiode, die dem menschlichen Auge entspricht

Computer mit Copyright-Software zur Steuerung und Protokollierung des gesamten Setups

in italiano:

Buy smoke density test 61034 è tutto sulla valutazione della plastica utilizzata su un cavo. Questo test è anche integrato con il nuovo regolamento CPR in Europa per i cavi in EN 50399 e EN 50750.

In caso di incendio, il fumo ha molti effetti, uno dei peggiori è la riduzione della visibilità.

Ritarda la fuga dagli edifici, in quanto il fumo viene rapidamente percepito come una barriera impenetrabile

che influisce sulla respirazione e irrita gli occhi. La visibilità (m) è valutata attraverso il fumo

opacità, calcolandone la densità ottica, il coefficiente di estinzione o la trasmittanza.

Infine, l’effetto dell’opacità sulle persone è determinato utilizzando modelli che prendono in considerazione

spiegare l’oggetto che vogliono vedere attraverso il fumo.

3.1 Trasmissione

La trasmissione è il rapporto tra l’intensità della luce trasmessa attraverso il fumo e la luce incidente

intensità in condizioni specifiche. È adimensionale ed è solitamente espressa come

percentuale. Senza fumo il suo valore è del 100%, diminuendo con il rilascio di fumo.

I0: intensità luminosa misurata in assenza di fumo/trasmissione = 100%.

I: intensità della luce misurata con il fumo

3.2 Densità ottica

La legge Beer-Lambert definisce l’assorbimento della luce di un materiale, a seconda del suo

proprietà. Può essere utilizzato per determinare l’attenuazione della luce attraverso il fumo per

una determinata lunghezza del percorso. La densità ottica si ottiene solitamente misurando la

attenuazione di un fascio di luce che passa attraverso il fumo, secondo la legge di Lambert-Beer.

Uno dei principali metodi di prova nell’industria dei cavi per valutare il fumo

il potenziale di produzione in caso di incendio è descritto nelle norme IEC/EN61034-1 e -2

standard. I cavi sono posizionati sopra un serbatoio contenente una specifica fonte di incendio, principalmente

etanolo, in una cabina da 27 m3 .

Quando i materiali del cavo bruciano, viene rilasciato del fumo,

riducendo l’intensità della luce nella camera di prova. Questa attenuazione è misurata da un

fotocellula posta davanti ad un fascio di luce bianca a distanza fissa: lunghezza del percorso di 3 m.

Il risultato finale è dato in termini di trasmittanza, (%). Senza altri

il normale criterio di pass/fail è il 60% della trasmittanza della luce.

L’apparecchiatura è composta da:-

un cubo di 3 metri a doppia parete con una camera d’acciaio di 2 mm di spessore

Ventola di miscelazione

Sistema di scarico

Pannelli a fiamma

Vassoio di etanolo

Portacampioni

La sorgente luminosa di 3500-3000K

Diodo di rilevamento a luce bianca equivalente all’occhio umano

Computer con software di copyright per il controllo e il reporting dell’intero setup

En français:

Acheter le test de densité de fumée 61034 concerne l’évaluation du plastique utilisé sur un câble. Ce test est également intégré à la nouvelle réglementation CPR en Europe pour les câbles dans les normes EN 50399 et EN 50750.

En cas d’incendie, la fumée a de nombreux effets, l’un des pires étant la réduction de la visibilité.

Elle retarde l’évacuation des bâtiments, car la fumée est rapidement ressentie comme une barrière impénétrable

affectant la respiration et irritant les yeux. La visibilité (m) est évaluée à travers la fumée

opacité, en calculant sa densité optique, son coefficient d’extinction ou sa transmittance.

Enfin, l’effet de l’opacité sur les personnes est déterminé à l’aide de modèles qui prennent en compte

de l’objet qu’ils veulent voir à travers la fumée.

3.1 Transmission

La transmission est le rapport entre l’intensité de la lumière transmise à travers la fumée et la lumière incidente

dans des conditions spécifiées. Elle est sans dimension et est généralement exprimée sous la forme d’une

pourcentage. Sans fumée, sa valeur est de 100%, diminuant avec le dégagement de fumée.

I0 : intensité lumineuse mesurée en l’absence de fumée/transmission = 100%.

I : intensité lumineuse mesurée avec de la fumée

3.2 Densité optique

La loi de Beer-Lambert définit l’absorption de lumière d’un matériau, en fonction de son

propriétés. Il peut être utilisé pour déterminer l’atténuation de la lumière à travers la fumée pour

une longueur de trajet donnée. La densité optique est généralement obtenue en mesurant la

l’atténuation d’un faisceau lumineux traversant la fumée, en utilisant la loi Lambert-Beer.

L’une des principales méthodes d’essai utilisées dans l’industrie du câble pour évaluer l’atténuation des fumées

Le potentiel de production en cas d’incendie est décrit dans les normes CEI/EN61034-1 et -2

normes. Les câbles sont placés au-dessus d’un réservoir contenant une source d’incendie spécifique, principalement

de l’éthanol, dans une cabine de 27 m3.

Lorsque les matériaux des câbles brûlent, de la fumée est dégagée,

réduire l’intensité lumineuse dans l’enceinte d’essai. Cette atténuation est mesurée par un

photocellule placée devant un faisceau de lumière blanche à une distance fixe : longueur de parcours de 3 m.

Le résultat final est donné en termes de transmittance, (%). Sans aucune autre

le critère normal de succès/échec est de 60 % de la transmission de la lumière.

L’équipement se compose de : –

une chambre cubique de 3 mètres à double paroi en acier de 2 mm d’épaisseur

Ventilateur de mélange

Système d’échappement

Panneaux de flammes

Plateau d’éthanol

Porte-échantillon

La source de lumière de 3500-3000K

Diode de détection de lumière blanche équivalente à l’oeil humain

Ordinateur avec logiciel de copyright pour le contrôle et le rapport de l’ensemble de l’installation

Smoke Density Tester IEC 61034

En español:

Comprar la prueba de densidad de humo 61034 se trata de la evaluación del plástico usado en un cable. Este ensayo también está integrado en la nueva normativa europea de RCP para cables en EN 50399 y EN 50750.

En caso de incendio, el humo tiene muchos efectos, siendo uno de los peores la reducción de la visibilidad.

Retrasa la salida de los edificios, ya que el humo se siente rápidamente como una barrera impenetrable.

afectando la respiración e irritando los ojos. La visibilidad (m) se evalúa a través del humo

opacidad, calculando su densidad óptica, coeficiente de extinción o transmitancia.

Finalmente, el efecto de la opacidad en las personas se determina utilizando modelos que toman en cuenta

cuentan el objeto que quieren ver a través del humo.

3.1 Transmitancia

La transmitancia es la relación entre la intensidad de la luz transmitida a través del humo y la luz incidente

intensidad en condiciones específicas. Es adimensional y se expresa generalmente como una

porcentaje. Sin ningún tipo de humo su valor es del 100%, disminuyendo con la emisión de humo.

I0: intensidad de la luz medida en ausencia de humo/transmitancia = 100%.

I: intensidad de la luz medida con el humo

3.2 Densidad óptica

La ley Beer-Lambert define la absorción de luz de un material, dependiendo de su

propiedades. Se puede utilizar para determinar la atenuación de la luz a través del humo para

una longitud de camino determinada. La densidad óptica se obtiene normalmente midiendo la

atenuación de un haz de luz que pasa a través del humo, utilizando la ley de Lambert-Beer.

Uno de los principales métodos de ensayo en la industria del cable para evaluar el humo

El potencial de producción en caso de incendio se describe en la norma IEC/EN61034-1 y -2

estándares. Los cables se colocan encima de un tanque que contiene una fuente de fuego específica, principalmente

etanol, en una cabina de 27 m3.

Cuando los materiales del cable se queman, se libera humo,

reduciendo la intensidad de la luz en la cámara de pruebas. Esta atenuación se mide con un

fotocélula colocada delante de un haz de luz blanca a una distancia fija: longitud del recorrido de 3 m.

El resultado final se da en términos de transmitancia, (%). Sin ningún otro

El criterio normal de pasa/falla es el 60% de la transmisión de luz.

El equipo consiste en:-

Cubo de 3 metros de doble pared con cámara de acero de 2 mm de espesor

Ventilador mezclador

Sistema de escape

Paneles de llama

Bandeja de etanol

Portamuestras

La fuente de luz de 3500-3000K

Diodo detector de luz blanca equivalente al ojo humano

Computadora con software de derechos de autor para el control e informe de toda la configuración.

You can also check out our more Machinery Products.

Smoke Density Tester IEC 61034