Cold Bend Test | Cold Impact Test

IEC 60811-504 describes the cold bend test method for cables under low temperatures. The cold bend test on cable is only possible upto a maximum diameter of 12.5mm. The test is mainly conclusive to understand the flexibility and strength of plastic used over cable under low temperatures.

Whereas cold impact test on cables is performed according to IEC 60811-506. This test is mainly designed to simulate the plastic’s capacity to resist mechanical shock under cold environment.Here from a certain height, mandrels of specific weight are dropped on the cable.

Among cable and plastic test equipment, Cold resistance-related tests are very important. Cold bend and cold impact test tools are made of higher quality steel grade to resist up to -100 deg cel temperature. These tools are used to asses a cable outer jacket or insulation strength in the low-temperature environment.

Buy these tools which come with the metal mandrel as well as different weights of mandrels according to IEC-60811. The NABL accredited calibration of weights is also supplied together with the instrument.

These tools can also be integrated and fixed or kept flexible on customer’s demand. The major mistakes committed by testing personnel with these tests is that they take out the cable from the Cold chamber and then test the bending or impact on cable samples. however this is actually prohibited by the norms if interpreted right.

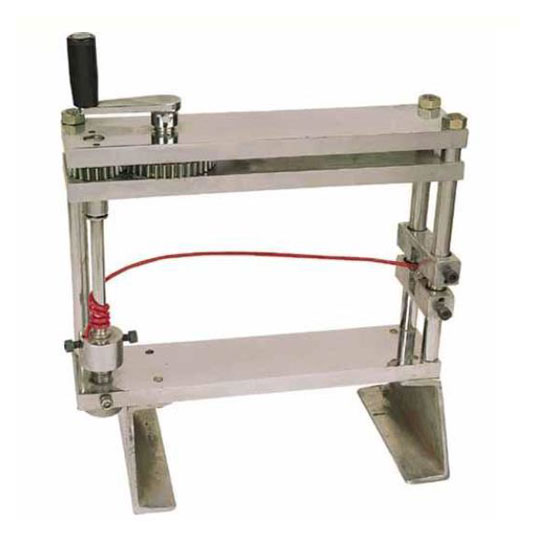

The cold bend test tools consist of:-

- Metal Mandrel.

Metal Frame for mandrel attachment

The cold impact test tools consist of:-

- Testing Anvil

- Cylindrical falling hammer.

- 10 weights as per IEC specs